I recently got around to repairing a domestic fridge that’s been kicking around in my workshop for probably 2 years now. It belonged to a neighbour that didn’t want to fork out the amount for a new control board and new compressor and dumped it with me. It was originally an R600 (isobutane) unit and I’m not keen to work with highly flammable/explosive refrigerants but eventually I came across a suitably sized, second hand, 134A compressor and found myself with some playtime the other day so I flushed it, vacuumed it and converted it.

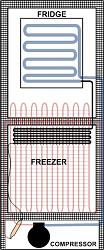

It's a pretty standard almost-frost-free type of fridge, it has an finned, static evaporator coil inside the freezer cabinet and a standard evaporator plate in the back wall of the fridge compartment. Both evaporators are in series with the freezer fed first by capillary and the chiller/fridge getting fed second from the freezer left-overs as it were. The condenser is the standard black steel convection type that stands proud at the back.

Instead of installing an extortionately priced new manufacturers control board that did almost nothing other than temp control by 4 x presets and would take 3 weeks to arrive I installed a generic 2-probe refrigeration controller which gave me the advantage of being very accurate temperature control, being able to more tightly control the defrost cycle, a temperature display accurate to 0.1 degrees and alarm facility if the fridge ever stops working and my food starts defrosting.

I ran the fridge and it turned out the 134A compressor was fractionally oversize by what’s known in professional engineering circles as a ‘ball hair’. After I got it down to normal operating temp and balanced the refrigerant charge it was very very close to being in a vacuum on the suction side. With a substantially oversize compressor it can result in condensing noise and under condensing/running hot but none of these symptoms were present and it ran well.

It was early evening in my workshop when I tested the fridge, it was empty and it took about 1 hour to get from 30 degrees to 2 degrees internal cabinet temperature at which point the controller shut off the compressor. Not wanting to hang around any longer I threw a power monitor on the fridge power supply to record the on and off times throughout the night so I could see in the morning if there were any problems.

Next day I checked the power log and everything was as expected. I could see the running periods and the off periods once the set temperature was reached and I could also see the defrost period that happened for 15 minutes in the early morning. From the regular pattern of the power log the fridge was running for around 10-12 minutes and then remained off for approx 35 minutes. Great I thought...success, a nice cheap fridge I can use at home for the bulk monthly shopping stuff so I promptly located it in my laundry room next to the small chest freezer.

Reply With Quote

Reply With Quote .

.

Did you like this article? Share it with your favourite social network.